Ok, I have a good idea of what I want in a final electrical solution. It needs to be reliable, flexible extensible and it needs to have enough capacity that I don't have to worry about how I use it (within reason).

Immediately, I knew I was going to go with Victron chargers and battery management components. They're a little more expensive than other options on the market, but they're good quality and they offer nearly everything with Bluetooth integration which meant I could keep all the insight and control I wanted without needing to mount a whole bunch of control panels and crawl around to use them.

Power Storage

I wanted, and ordered, a pair of 200AH Lithium batteries but they got caught up in a COVID-related shipping disaster and ultimately I decided it wasn't worth holding off on the project and moved forward with purching some surprisingly good, cheap, Gel Deep-Cycle batteries. Because of how I've designed my battery storage location, I bought 3 of those batteries to maximize the space.

2 100AH Gel Deep-Cycle Batteries

All the high-current protection in the system is provided by MRBF Terminal Fuses, which you can see mounted onto every battery. I'm a big fan of those fused terminal blocks, as it means there is no un-protected cable in the system and a short failure of one battery won't damage the others. I used some cheap foam appliance pads to make sure the batteries didn't shift around even though in my testing they were really solid in there without it. I wouldn't advocate for this design, but it does seem to work OK and everything is fused and protected and it's all also held down from the top so I'm sure it's not a problem.

Great, that has the batteries taken care of. Since these are native 12v batteries there's no voltage conversion required for my 12v appliances and they can run low-draw appliances extremely efficiently. And given the size of the bank, they also have no issues running high-current loads when needed. Everything is protected, and secured.

Charging

Ok, with storage out of the way how are we charging these things? I wanted to have a redundant, flexible and reliable solution for charging. With that in mind, the main charging components of this system are:

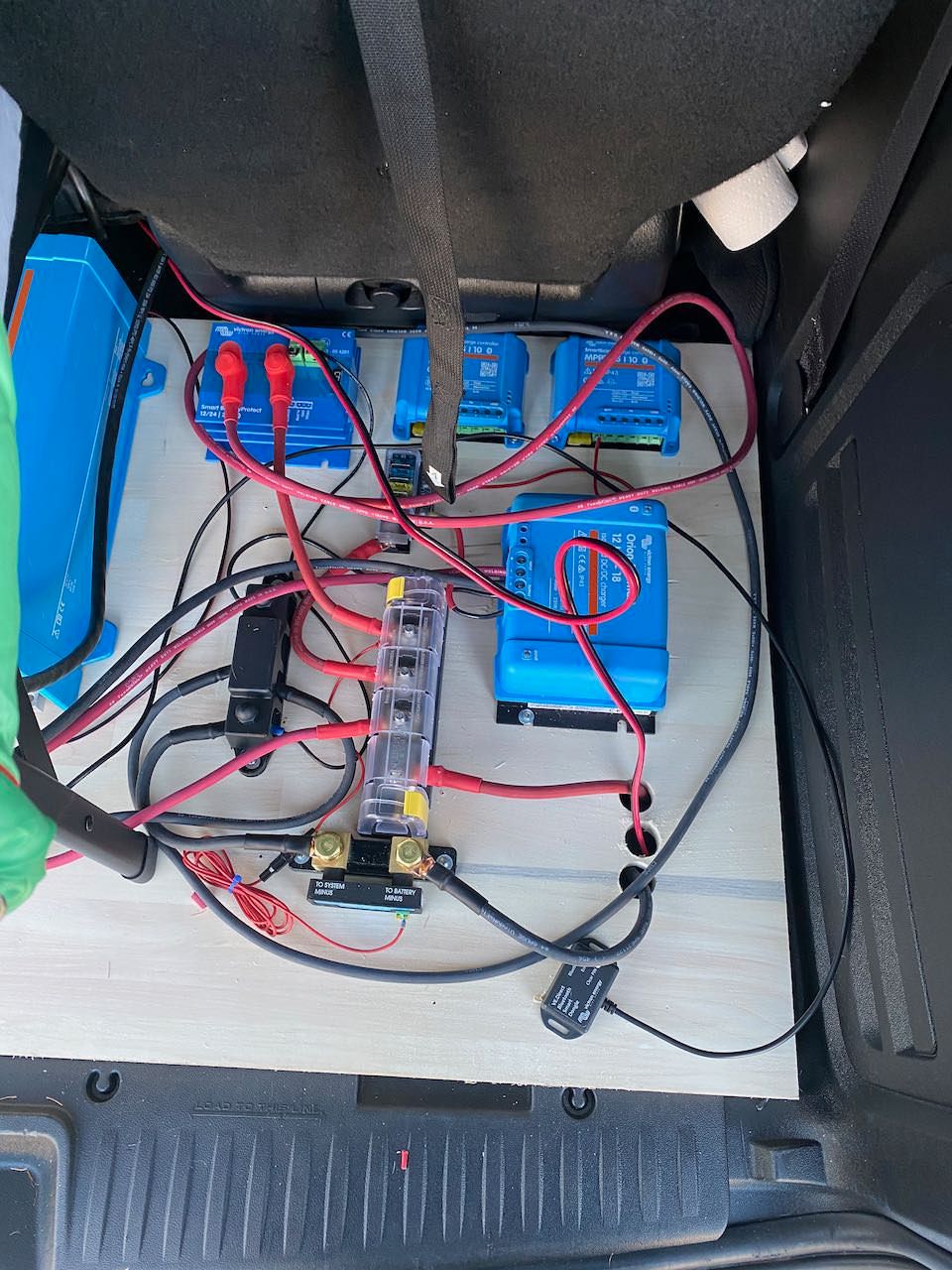

- (2) Victron SmartSolar MPPT 75v 10A Solar Charge Controller

- 170 Watt Rich Solar Panel

- (2) 60 Watt Portable Rich Solar Panel

- Victron Orion-Tr Smart 18 Amp Isolated DC-DC Charger

- Victron BlueSmart 12v 15A Charger

This solution provides up to ~200 watts of AC charging (shore power), up to ~220 watts of Alternator (engine) charging, and up to~ 270 watts of solar charging.

Solar panel installation

These chargers are all indivudually fused on a dedicated charging fuse panel. That means any charger can be simply isolated, and any faults are isolated between chargers. Each of these chargers is individually able to meet my projected electrical demands easily, so this solution provides a flexible and redundant solution for keeping the juice flowing.

Management

Since I'm using batteries with no built-in protection it's important to shut off loads when they could damage the battery bank. It's also helpful to have an accurate "state of charge" reading of the bank. To accomplish this, it's more Victron components, namely:

These devices provide excellent visibility and control over my battery loads and the flow of power to and from the battery.

Loads

So, what does all this power? Well, there are two main feeds coming from the electrical system to power loads. One of them is simply a Victron 1200VA Inverter with Bluetooth dongle. This provides a source of 120v power for things (like my work laptop or instant pot) that require it. Everything else is a native 12v device, or USB powered device and that's all controlled through my control hub.

It's not the prettiest thing on the outside, but trust me the inside is far worse. This switch panel comes with some pretty bizarre wiring (the fuses are on the output of the switches, but with a very under-sized common feed for example), but it was pretty easy to fix that up and wire everything to common 12v feed and ground posts. The 120v outlets are fed from an automatic transfer switch that I'll cover later, but everything else is fed from the Smart Battery Protect. The switches, from left to right, are:

- Inverter Control

- Wifi Power

- Internal Comfort (electric blanket, etc.)

- Internal Critical (fridge, water, etc.)

- Convenience (12v front outlet, USB ports, voltage gauge)

This is mounted inside in a convenient spot so I can control everything easily, and easily see what's powered up at any given time.

About those 120v outlets...

I ultimately settled on a relatively convoluted but flexible solution to feeding those. The outlets in the box are fed directly from an automatic transfer switch, which has responsibility for selecting whether shore power or the inverter will be powering those outlets. That transfer switch is connected to the Inverter as well as to a GFCI Breaker feed from my shore-power lead. The inverter control lead is powered by the control hub, so it is protected by the Battey Protect, even though the feed wiring bypasses it for compatibility reasons.

How does it all look together?

Alright, it's not a pretty install. For now I wanted to keep everything visible and servicable with simple tools. Everything is cabled with high-quality welding cable, and the feed from the alternator runs underneath the van and is futher protected by some plastic split-loom conduit. The wires are all extremely over-sized for their loads, and everything is heavily protected through redundant fuses and digital protection routines.